While some are still arguing about wearing masks a year after the pandemic, scientists have got to work figuring out which strategy is best – and cotton face masks have just gotten another sign of approval.

Several studies have tested different material combinations, and health authorities such as the World Health Organization and the CDC are recommending cloth masks to the general public, based on their conclusions. But some of these studies overlooked an important real-life factor: these face-covering substances become moist with our breath.

Now, a team of researchers has tested mask materials under high-humidity conditions that mimic the air expelled from our mouths.

“This new study shows that cotton fabrics actually perform better in masks than we thought,” said materials scientist Christopher Zangmeister of the US National Institute of Standards and Technology (NIST).

Zangmeister and colleagues tested nine different types of cotton and six types of synthetic fibers, including polyester and rayon, in 99 percent humidity (roughly how moist our breath is) and 55 percent humidity.

This resulted in a noticeable visible difference in the performance of cotton.

Cotton masks become better filters when they absorb the moisture from your breath, helping them slow down COVID-19 even better than we thought: https://t.co/qbGtnC4a42 pic.twitter.com/91hNVIvlTX

– National Institute of Standards and Technology (@NIST) March 9, 2021

While synthetics, which also performed poorly compared to dry cotton, did not change performance in humid conditions, cotton fabrics increased their ability to trap particles by 33 percent.

The researchers used salt particles of various sizes as a test substitute for virus-transporting droplets and aerosol particles, and these appeared to absorb some of the moisture trapped by the hydrophilic cotton fibers. The particles swell in volume, making it more difficult for them to pass through the fabric unhindered.

However, synthetic fibers repel water and thus do not create the moist environment within the mask itself for this inhibition to take place. There was also no change in medical masks, but they are designed to work at a high level (similar to cotton) under all conditions.

According to the results, cotton flannel was the best performing cotton.

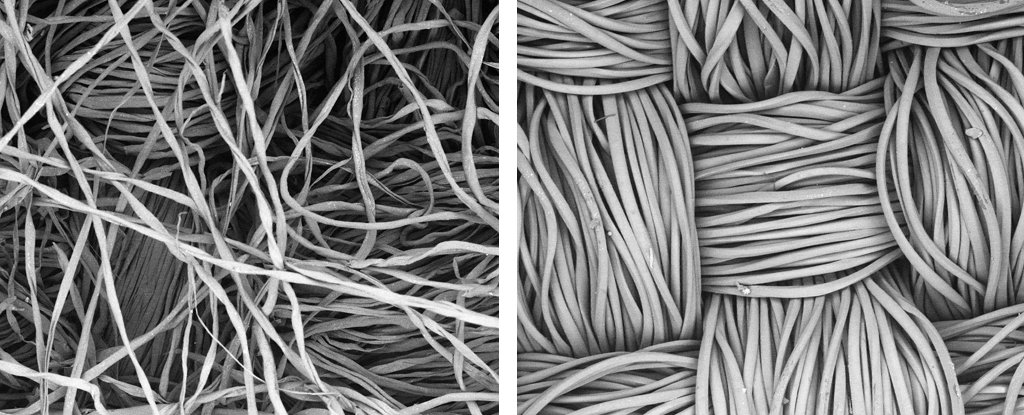

Microscopic images of the materials reveal a marked difference in structure – an orderly weave in synthetic polyester compared to the chaotic network of crisscrossing fibers that makes flannel soft to the touch.

NIST researchers believe this mess of fibers increases the likelihood that airborne particles passing through the mask will collide and stick to the fabric.

Cotton flannel (left), polyester (right). (EP Vicenzi / Smithsonian Museum / NIST)

Cotton flannel (left), polyester (right). (EP Vicenzi / Smithsonian Museum / NIST)

However, all of this doesn’t mean wet masks are better: if your mask gets wet, it should be replaced. The amount of liquid present in the masks in these humid conditions is only a few drops, which does not change the breathability of the material – the team found that the air pressure on both sides of the fabric remained relatively equal.

This is also good news from an environmental point of view. With assembly scraps from disposable surgical masks that shed microplastics, it’s reassuring to know there is a safe, reusable option.

Research suggests that owning some reusable masks that can be machine washed together is the most eco-friendly option for protecting you and your loved ones.

While the team says more research is needed to fully appreciate the interactions between masks, humidity and aerosol particle transfer, their research contributed to the first international standards for fabric masks intended to slow the spread of COVID-19, recently released. by the standards-building organization ASTM International.

“To understand how these materials perform in the real world, we need to study them under realistic conditions,” concluded Zangmeister.

This research is published in Nanomaterials used by ACS