As China pushes the world to avoid official contacts with Taiwan, leaders around the world are realizing how dependent they have become on island democracy.

Taiwan, which China considers a province, is being courted for its ability to make advanced computer chips. That’s largely because of Taiwan Semiconductor Manufacturing Co., the The world’s largest foundry and go-to maker of chips for Apple Inc. smartphones, artificial intelligence and high-performance computing.

Taiwan’s role in the global economy was largely under the radar until the time came recent notoriety when the auto industry was struggling with shortages of chips used for everything from parking sensors to reducing emissions. Now car manufacturers including the German Volkswagen AG, Ford Motor Co. from the USA and Japan’s Toyota Motor Corp. forced to shut down production and factories down, Taiwan’s importance has suddenly become too great to ignore.

American, European and Japanese carmakers are lobbying their governments for help, asking Taiwan and TSMC to intervene. Chancellor Angela Merkel and President Emmanuel Macron discussed the potential for shortages last year and agreed on the need to accelerate Europe’s push to develop its own country. chip industry, according to a knowledgeable French official.

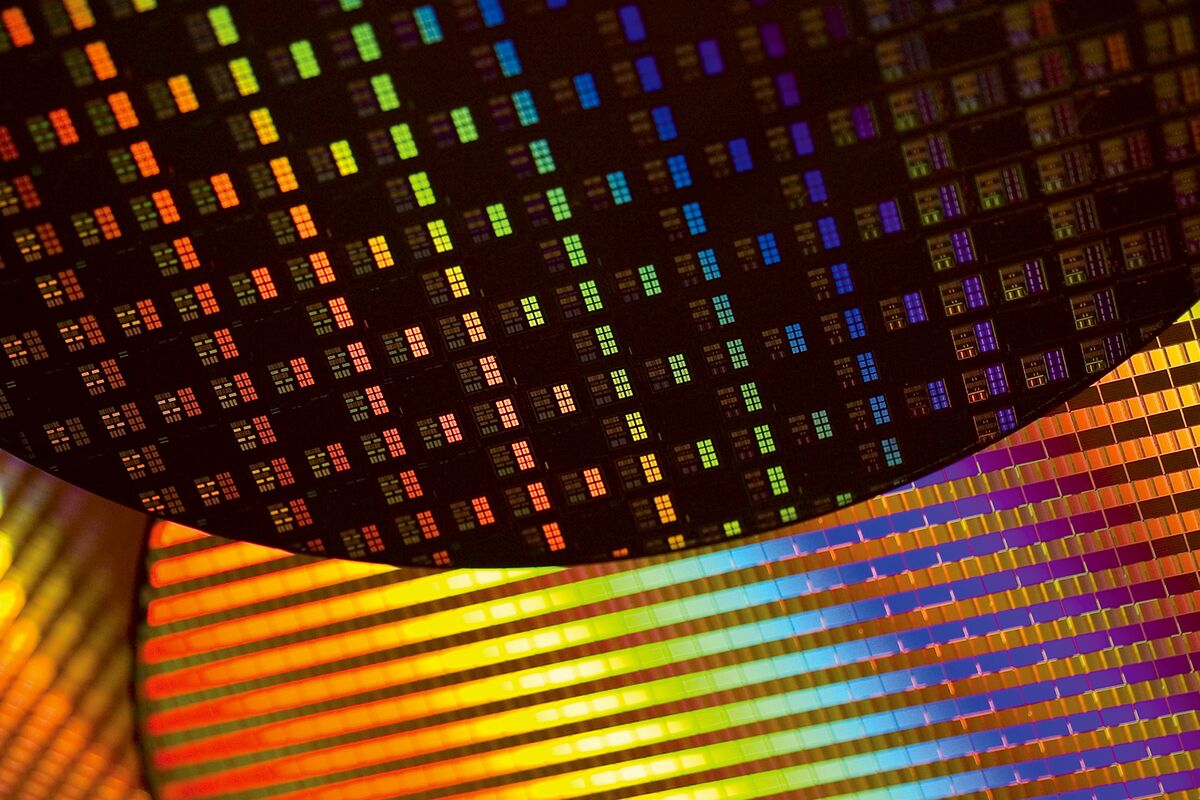

Wafers manufactured by TSMC. Taiwan is a bottleneck in the global semiconductor supply chain.

Source: Taiwan Semiconductor Manufacturing Co.

The automotive industry’s pleas illustrate how TSMC’s chip-making skills have given Taiwan political and economic leverage in a world where technology is harnessed in the great power rivalry between the US and China – an impasse that is unlikely to disappear under the Joe Biden government.

Taiwan’s grip on the semiconductor industry – despite the constant threat of invasion from Beijing – is also a bottleneck in the global supply chain, adding new urgency to plans from Tokyo to Washington and Beijing to increase self-reliance.

By dominating the US-developed chip manufacturing outsourcing model, Taiwan is “potentially the most critical single point of failure in the entire semiconductor value chain,” said Jan-Peter Kleinhans, director of the technology and geopolitics project at the think tank in Berlin. Stiftung Neue Verantwortung.

The Trump administration took advantage of that bottleneck to deny Beijing access to technology. By banning access to all US chip technology, including design, it was able to cut off semiconductor supplies from TSMC and other foundries to Huawei Technologies, hindering the advance of China’s largest technology company.

It also negotiated with TSMC to establish a $ 12 billion chip manufacturing facility in Arizona. The South Korean Samsung Electronics Co. will follow, with a $ 10 billion facility in Austin, Texas.

The “CHIPS for America Act” introduced in Congress last year aims to encourage the establishment of more plants in the US. Michael McCaul, a Texas Republican, plans to reintroduce the bipartisan law this year for the purpose of securing $ 25 billion in federal funds and taxes. incentives. McCaul said in a statement that he is working with colleagues in the House and Senate “to prioritize signing the remaining provisions of CHIPS as soon as possible.”

The news that Intel Corp., the former industry leader, was considering outsourcing production of some chips to TSMC under its former CEO, underscored the need for a US player capable of industry-leading manufacturing, said a Foreign Affairs Committee employee who did not authorized to speak in public.

The European Union wants to strengthen the bloc’s ‘technological sovereignty’ through an alliance initially armed with a whopping € 30 billion ($ 36 billion) in public-private investment to increase Europe’s share of the global chip market to 20% (no target date.) Of less than 10% now.

The site of ASML Holding NV in Veldhoven, the Netherlands. ASML has a monopoly on the machines needed to make the best chips.

Photographer: Jasper Juinen / Bloomberg

It also encourages Taiwan to invest more in the 27-country bloc, with some success. GlobalWafers Co. – based in TSMC’s hometown of Hsinchu – just increased its offer to Germany’s Siltronic AG to value the company at $ 4.4 billion, an acquisition that would create the largest maker of silicon wafers by revenue.

That’s not to say Taiwan is the only player in the semiconductor supply chain. The US still has a dominant position, especially in chip design and electronic software tools; ASML Holding NV from the Netherlands has a monopoly on the machines needed to manufacture the best chips; Japan is a major supplier of equipment, chemicals and wafers.

But as the emphasis shifts to smaller, more powerful chips that require less energy, TSMC is increasingly in a field of its own. And it has helped Taiwan form an extensive ecosystem around it: ASE Technology Holding is the world’s best chip assembler, while MediaTek has become the largest supplier of chipsets for smartphones.

Tokyo is also trying to attract TSMC to settle in Japan. With 110 billion yen ($ 1 billion) set aside for R&D investment last year and another 90 billion yen for 2021, some of that could go to a TSMC facility, which reports that the company is considering establishing in Japan .

“TSMC is becoming increasingly dominant,” said Kazumi Nishikawa, an official dealing with technology issues at Japan’s Ministry of Economy. “This is something that everyone in the chip industry needs to find a way to deal with.”

China, in its five-year plan presented in October, channels aid to the chip industry and other key technologies to the tune of $ 1.4 trillion through 2025. But even that kind of money doesn’t nullify the need for Taiwan. Indeed, China has long tapped the island for potato chips making talent; two key executives at China’s top chip maker, Semiconductor Manufacturing International Corp., worked at TSMC: Co-Chief Executive Officer Liang Mong Song and Vice Chairman Chiang Shang-yi.

But with Washington hampering China’s progress, there is also speculation that Beijing could resort to chip IP stealing, with Taiwan at the heart of those efforts.

Taiwanese cybersecurity firm TeamT5 has seen a steady increase in attacks on the island’s chip industry, in line with the tightening of US export controls on China. While it’s not always possible to know whether these are Chinese state actors, “they are all attacking the Taiwanese semiconductor industry,” said Shui Lee, a cyber threat analyst at T5.

Fellow analyst Linda Kuo said the Taiwanese government was alarmed by a ransomware attack on TSMC in 2018 and announced plans for about $ 500 million to help the industry become more aware of cybersecurity concerns.

In TSMC’s 12-inch wafer fab. Taiwanese cybersecurity firm TeamT5 has seen a steady increase in attacks on the island’s chip industry, in line with the tightening of US export controls on China.

Source: Taiwan Semiconductor Manufacturing Co.

The bigger concern is that TSMC’s chip factories could become collateral damage if China made up for threats to invade Taiwan as it moves towards independence.

TSMC’s capital expenditures of a whopping $ 28 billion for this year suggests it will stay ahead.

“Taiwan is the center of gravity of China’s security policy,” said Mathieu Duchatel, director of the Asia program at the Institut Montaigne in Paris. But while Taiwan’s status in the global chip supply chain is a “tremendous strategic value,” it is also a powerful reason for Beijing to stay away, said Duchatel, who just published a policy paper on China’s pursuit of semiconductors.

Assuming Taiwanese forces would be overwhelmed during an invasion, “there is no reason they would leave these facilities intact,” he said. And maintaining the world’s most advanced factories “is in everyone’s interest.”

Despite all the steps to reduce domestic chip manufacturing, it is optimistic to think that the supply chain for such a complex product as semiconductors could change in the near term, Peter Wennink, CEO of ASML, told Bloomberg TV. “If you want to reassign the semiconductor building capacity, the manufacturing capacity, you have to think in years,” he said.

In the meantime, geopolitics means that chip shortages are more common, said Joerg Wuttke, president of the EU Chamber of Commerce in China.

“This will go so far as, in fact, because of export controls, because of government intervention, there will be sudden disruptions to the supply chain, not just capacity problems,” he told Bloomberg Television. “So be prepared.”

– Assisted by Natalia Drozdiak, Debby Wu, Ellen Proper, Birgit Jennen, Francine Lacqua, Matthew Miller and Gem Atkinson