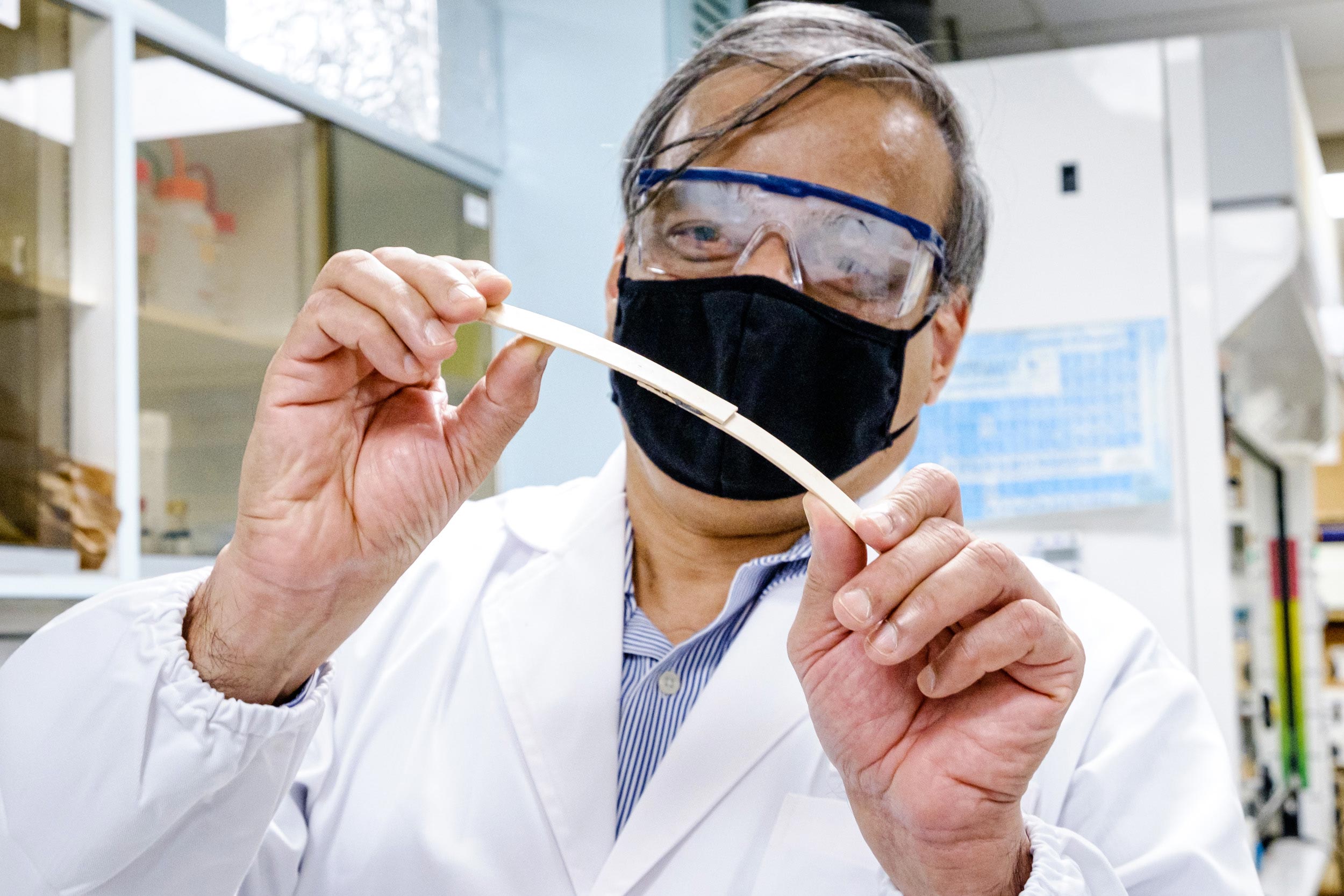

NTU Prof Raju holds and bends two pieces of wood joined in the center by the magnetically curing adhesive to demonstrate the strong bonding power. Credit: NTU Singapore

The new adhesive is a potential boon to green production and saves energy, time and space.

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a new way to cure adhesives using a magnetic field.

Conventional adhesives such as epoxy used to bond plastics, ceramics and wood are usually designed to cure using moisture, heat or light. They often require specific cure temperatures ranging from room temperature to 80 degrees Celsius.

The curing process is necessary for the adhesive to crosslink and bond with the two adhered surfaces while the adhesive crystallizes and hardens to reach its final strength.

NTU’s new “magnetocuring” adhesive can heal by passing it through a magnetic field. This is very useful in certain environmental conditions where current adhesives do not work properly. When the adhesive is sandwiched between insulating material such as rubber or wood, traditional activators such as heat, light and air cannot easily reach the adhesive.

Products such as composite bicycle frames, helmets and golf clubs are currently made with two-part epoxy adhesives, where a resin and a hardener are mixed and the reaction starts immediately.

For carbon fiber manufacturers – thin ribbons of carbon glued together layer by layer – and carbon fiber sports equipment makers, their factories use large high-temperature furnaces to cure the epoxy adhesive for many hours. This energy-intensive curing process is the main reason for the high cost of carbon fiber.

The new “magnetocuring” adhesive is made by combining a typical commercially available epoxy adhesive with specially tailored magnetic nanoparticles made by the NTU scientists. It does not need to be mixed with a hardener or accelerator, unlike two-component adhesives (which contain two liquids that must be mixed before use), making it easy to manufacture and apply.

It binds the materials when activated by passing a magnetic field, which is easily generated by a small electromagnetic device. This consumes less energy than a large conventional oven.

Assoc Prof Steele (left) and Dr. Richa cure the magnetically curing adhesive on a cotton gauze using an electromagnetic field. Credit: NTU Singapore

For example, one gram of magnetically curing adhesive can be easily cured by a 200 watt electromagnetic device in five minutes (consumes 16.6 watt hours). This requires 120 times less energy than a traditional 2000 watt oven, which takes an hour (2000 watt hours) to cure conventional epoxy.

Developed by Professor Raju V. Ramanujan, Associate Professor Terry Steele and Dr. Richa Chaudhary of the NTU School of Materials Science and Engineering, the findings were published in the scientific journal Applied materials today and offer potential applications in a wide variety of fields.

This includes high-quality sporting goods, automotive products, electronics, energy, aerospace and medical manufacturing processes. Laboratory tests have shown that the new adhesive has a strength of up to 7 megapascals, comparable to many of the epoxy adhesives on the market.

Assoc Prof Steele, an expert in various types of advanced adhesives, explained: “Our main development is a way to cure adhesives within minutes of exposure to a magnetic field, while preventing overheating of the surfaces on which they are applied. This is important because some of the surfaces we want to bond are extremely heat sensitive, such as flexible electronics and biodegradable plastics. ”

How “magnetocuring” glue works

The new adhesive is made from two main components: a commercially available epoxy that is heat-cured and oxide nanoparticles made from a chemical combination of manganese, zinc and iron (MnxZn1-xFe2O4).

These nanoparticles are designed to heat up when electromagnetic energy is passed through them, triggering the curing process. The maximum temperature and heating rate can be controlled by these special nanoparticles, eliminating overheating and hot spot formation.

(Left to right) NTU Assoc Prof Terry Steele, Prof Raju V. Ramanujan and Dr Richa Chaudhary hold various soft and hard materials bonded by their new magnetically curable adhesive. Credit: NTU Singapore

Without the need for large industrial furnaces, the adhesive activation has a smaller footprint in terms of space and energy consumption. Energy efficiency in the curing process is critical to green manufacturing, where products are made at lower temperatures and use less energy for heating and cooling.

For example, athletic shoe manufacturers often struggle to heat up the adhesives between the rubber soles and the top half of the shoe, as rubber is a heat insulator and resists heat transfer to the conventional epoxy adhesive. An oven is needed to warm up the shoe for a long time before the heat can reach the glue.

The use of magnetic field activated adhesive overcomes this difficulty by directly activating the curing process only in the adhesive.

The alternating magnetic field can also be embedded at the bottom of conveyor systems so that products with pre-applied adhesive can be cured as they pass through the magnetic field.

Improve production efficiency

Prof Raju Ramanujan, internationally recognized for his advancements in magnetic materials, jointly led the project and predicts that the technology can increase manufacturing efficiency where adhesive bonding is required.

“Our temperature-controlled magnetic nanoparticles are designed to be mixed with existing single-legged adhesive formulations so that many of the epoxy-based adhesives on the market can be converted into magnetic field-activated adhesives,” said Prof. Ramanujan.

“The speed and temperature of curing can be adjusted, so manufacturers of existing products can redesign or improve their existing production methods. For example, instead of applying glue and curing it part by part in a conventional assembly line, the new process could be to pre-apply glue to all parts and then cure them as they move along the conveyor chain. Without ovens, this would result in much less downtime and more efficient production. “

The study’s lead author, Dr. Richa Chaudhary, said: “Our newly developed magnetic-curing adhesive takes only minutes instead of hours to cure, and yet it is able to attach surfaces with very strong bonds, which is of great importance in sports. , automotive and aerospace industries. This efficient process can also deliver cost savings as the space and energy required for conventional heat treatment is significantly reduced. ”

This three-year project was supported by the Agency for Science, Technology and Research (A * STAR).

Previous work on heat-activated glue used an electric current flowing through a coil, known as induction curing, in which the glue is heated and cured from the outside. However, the drawbacks include overheating of the surfaces and uneven adhesion due to hot spots in the adhesive.

In the future, the team hopes to involve adhesive manufacturers in commercializing their technology. They have filed for a patent through NTUitive, the university’s innovation and entrepreneurship company. They have already gained interest in their research from sporting goods manufacturers.

Reference: “Magnetocuring of Temperature Resistant Epoxy Adhesives” by Richa Chaudhary, Varun Chaudhary, Raju V. Ramanujan and Terry WJ Steele, September 15, 2020, Applied materials today.

DOI: 10.1016 / j.apmt.2020.100824