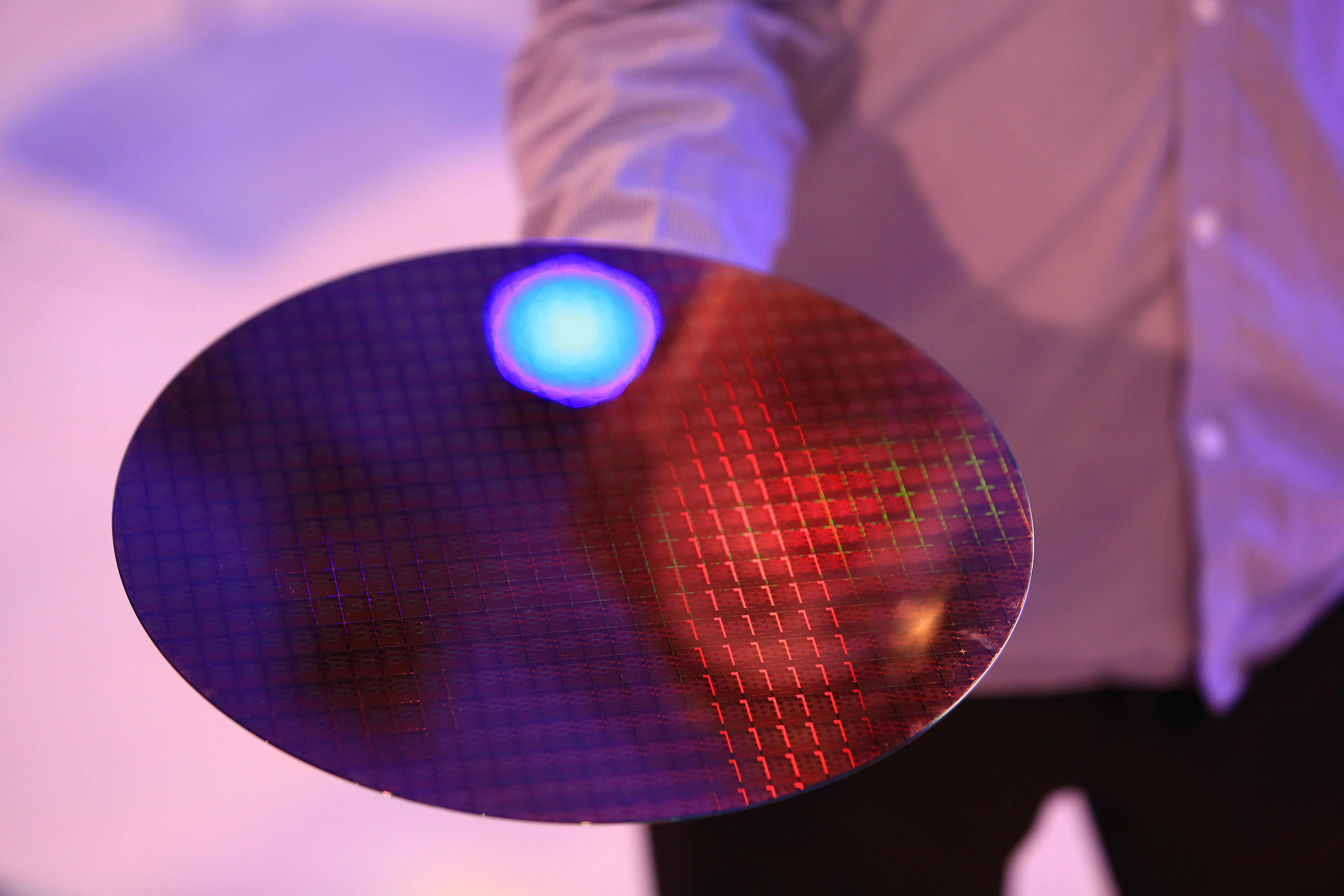

A semiconductor wafer at an Intel event prior to an IFA International Consumer Electronics Show.

Krisztian Bocsi | Bloomberg | Getty Images

Intel announced Tuesday that it will spend $ 20 billion to build two new chip factories called factories in Ocotillo, Arizona.

Intel shares were up a whopping 5% on the news in extended trading on Tuesday.

The announcement, which coincided with new CEO Pat Gelsinger’s first public comments since taking over the job, indicates that Intel will continue to focus on manufacturing during industry shifts that have driven competitors to increase chip design and chip manufacturing. go divorce.

The news comes amid a global chip shortage that is snapping industries from automobiles to electronics and concerns that the US is falling behind in semiconductor manufacturing.

“Intel is and will continue to be a leading developer of process technology, a major semiconductor manufacturer and the largest supplier of silicon worldwide,” said Gelsinger.

Intel also said it will act as a “foundry” or manufacturing partner for other chip companies that focus on semiconductor design but need a company to actually make the chips. Intel said its foundry subsidiary will be called Intel Foundry Services and will be led by Randhir Thakur, a current Intel senior vice president.

Gelsinger said the foundry company will compete in a market potentially worth $ 100 billion by 2025 and will produce a range of chips, including ARM-based chips, used in mobile devices, and have historically competed with Intel’s favorite x86. -technology.

A slide shown by Intel suggested companies like Amazon, Google, Microsoft and Qualcomm could be customers for the company. Satya Nadella, Microsoft’s CEO, appeared on a show of support for Intel’s move during Gelsinger’s lecture.

Why Intel opens new factories

Intel’s commitment to manufacturing has implications for national security. Intel said it is partnering with IBM to improve chip logic and packaging technologies that “will increase the competitiveness of the US semiconductor industry and support major US government initiatives.”

Intel currently operates four factories called “wafer factories” in the United States. In addition to its Arizona location, which is being expanded, it also has plants in Massachusetts, New Mexico and Oregon. It also makes chips in Ireland, Israel, and has a single factory in China.

Intel’s foundry will provide a US and Europe-based alternative to Asian chip factories.

In February, President Joe Biden said domestic semiconductor manufacturing is a priority for his administration. His administration hopes to resolve the existing chip shortage and address legislators’ concerns that chip manufacturing outsourcing has made the US more vulnerable to supply chain disruptions.

In an executive action, Biden embarked on a 100-day review that could boost US chip companies with additional government support and new policies.

Today’s Executive Order, combined with full funding for the CHIPS Act, can help level the playing field in global competition for semiconductor manufacturing leadership, allowing US companies to compete on an equal footing with foreign companies heavily subsidized by their governments Intel said. the time in response to the executive order.

Gelsinger acquired Intel from former CEO Bob Swan on February 15. Although he was last the CEO of VMWare, he started his career at Intel and his appointment was considered a homecoming.

He took over a company that faced several challenges. Intel had lost its lead in semiconductor manufacturing to Asia-based rivals, TSMC in particular. Intel’s most advanced chips use a 14 nanometer or 10 nanometer process. Intel designs both chips and then makes them in its own factories called fabs.

But competitors, including Intel customers such as Apple and rivals such as AMD, simply design the processor and then have it manufactured by a third-party chip factory. These chip factories, such as TSMC and Samsung, use a more advanced 5 nanometer process, which is superior because more transistors can fit in the same chip, which increases power and efficiency.

“We’re aiming for customers like Apple” for Intel’s foundry business, Gelsinger said.

Gelsinger said Tuesday that its 7-nanometer chips are on track to hit a milestone in the second quarter and that it plans to produce the majority of its products itself. Still, Intel will increase the use of third-party foundries including TSMC, Samsung and GlobalFoundries, he said.

Intel also announced an annual guidance. The company said it expects $ 4.55 in adjusted earnings per share to be $ 72 billion, lower than Refinitiv’s estimates of $ 4.77 in adjusted earnings per share and $ 72.94 billion in revenue in revenue. Intel said it expects $ 19 billion to $ 20 billion in capital expenditures for the year. Analysts polled by FactSet had expected $ 14.59 billion.

CNBC’s Jordan Novet contributed to this story.