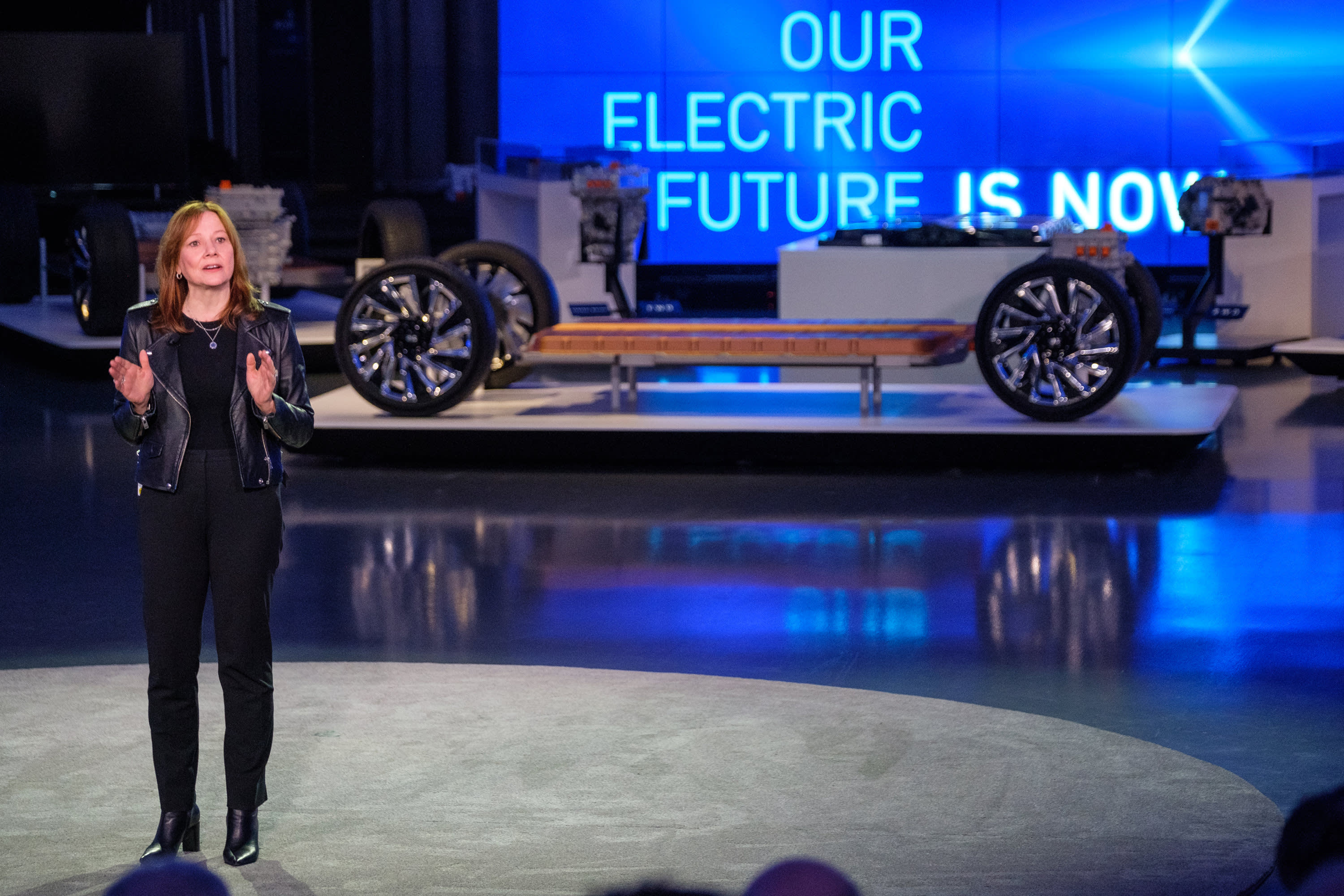

GM CEO and Chairman Mary Barra speaks at an “EV Day” on March 4, 2020 at the company’s tech and design campus in Warren, Michigan, a suburb of Detroit.

GM

General Motors and LG Chem of South Korea will invest more than $ 2.3 billion in a second US battery cell plant for electric vehicles in Tennessee, the companies announced Friday.

The plant for their Ultium Cells LLC joint venture will support production of GM’s upcoming Cadillac Lyriq crossover and other future EVs at a nearby assembly plant.

The supply and production of battery cells are crucial for car manufacturers turning to electric vehicles. The joint venture for the new plant, while the first is still under construction in Lordstown, Ohio, underlines this.

Construction of the approximately 2.8 million square foot facility will begin immediately. The plant will open in late 2023 and will create 1,300 jobs, according to the companies.

“The addition of our second all-new Ultium battery cell plant in the US with our joint venture partner LG Energy Solution is another important step in our transition to an all-electric future,” said Mary Barra, GM CEO, in a press release.

The announcement comes amid a 100-day review commissioned by President Joe Biden of the US supply chain for advanced batteries, pharmaceuticals, critical minerals and semiconductors. He ordered the revision amid a continuing global shortage of semiconductor chips that will significantly impact US automotive production in 2021.

GM confirmed last month that it was evaluating a second location in the US to produce battery cells for electric vehicles with LG. Reuters reported details of the announcement on Wednesday.

Jong Hyun Kim, president and CEO of LG Energy Solution, said the new facility will enable the companies to “build solid and stable supply chains in the US that enable everything from research, product development and manufacturing to raw material procurement. components. “

Some analysts, notably Morgan Stanley’s Adam Jonas, have warned of a potential shortage due to cell capacity compared to the number of new electric vehicles expected to hit the market in the coming years.

“In our view, GM’s creation of Ultium / Ultium Cells LLC will prove to be a critical point of strategic differentiation that will ultimately drive value creation for shareholders,” he said in a note to investors on Wednesday.

Ultium is GM’s next generation of batteries and platform, expected to debut in the GMC Hummer EV pickup this year. The first vehicles are not expected to contain Ultium battery cells from the Ohio plant under construction.

An undated photo shows the new Cadillac Lyriq, one of the electric vehicles that General Motors Co said the Spring Hill, Tennessee plant will start producing on October 20, 2020.

General Motors Co. | Reuters

GM is expected to continue building or converting factories to battery facilities in the US as it develops into an automaker offering exclusively electric vehicles by 2035. vehicles during that time frame.

Most batteries, like semiconductors, are manufactured in Asia and Europe. Tesla operates a massive battery and cell manufacturing facility with Panasonic in Nevada. Tesla also told investors in September that it was starting to manufacture its own cells at a pilot plant in Fremont, California.

GM and LG first announced the joint venture in December 2019.